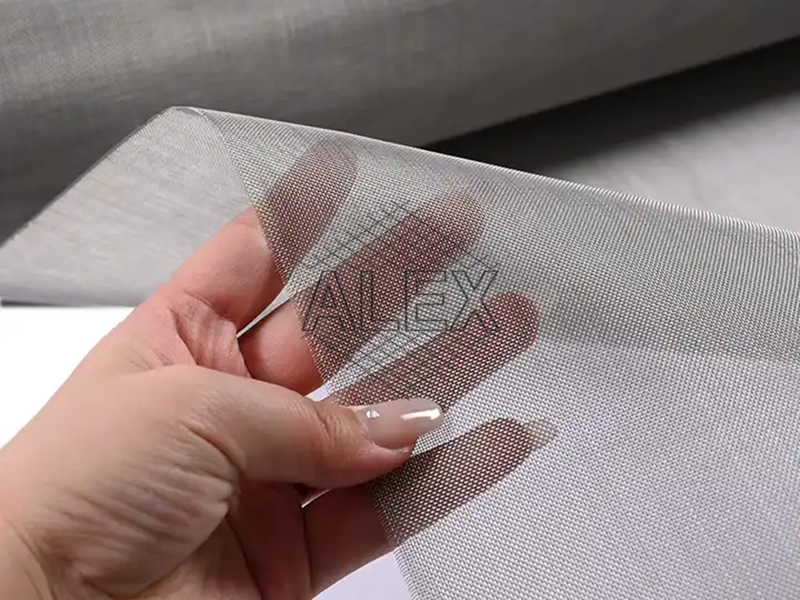

316 stainless wire screen is widely used in various industrial and commercial applications due to its excellent corrosion resistance and durability.

Stainless steel wire mesh features:

1. Corrosion resistance: 316 stainless steel offers superior resistance to corrosion, making it suitable for harsh environments.

2. Strength and durability: The wire screen is strong and resistant to wear, ensuring long-lasting performance.

3. High temperature resistance: It can withstand high temperatures without losing its structural integrity.

4. Versatility: The screen is available in various mesh sizes, wire diameters, and dimensions to suit different applications.

5. Easy maintenance: The smooth surface of the screen makes it easy to clean and maintain.

Stainless steel wire cloth advantages:

1. Longevity: The excellent corrosion resistance of 316 stainless steel ensures a longer lifespan compared to other materials.

2. Chemical resistance: It resists damage from exposure to chemicals, acids, and alkalis, making it suitable for diverse industrial environments.

3. Hygienic properties: The non-porous surface of the screen prevents the accumulation of dirt, bacteria, and contaminants.

4. Optimal visibility: The fine mesh design allows for clear visibility while providing effective filtration or separation.

Stainless steel wire screen usage:

1. Filtration and separation applications in industries such as oil and gas, petrochemical, and food processing.

2. Window screens and security screens for residential and commercial buildings.

3. Insect screens for doors and windows to prevent entry of pests while allowing ventilation.

4. Construction applications like reinforcing concrete structures and providing safety barriers.

5. Marine and coastal applications where resistance to saltwater corrosion is crucial.

6. Automotive and aerospace industries for air filtration and engine components.

7. Architectural applications for decorative purposes, such as facades and interior design elements.

8. Pharmaceutical and laboratory settings for sieving, particle analysis, and sterile environments.