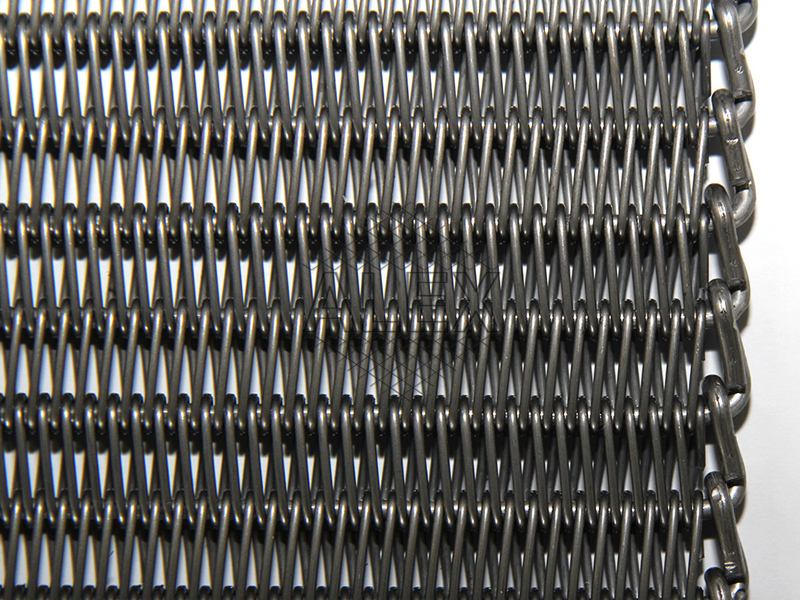

Clinch edge transport belt is the new type of conveyor belt which is manufactured using high-quality stainless steel.

It features a single-ply construction for durability and strength.

The wire belt width is available in various sizes ranging from 100mm to 2000mm.

Its thickness ranges from 1mm to 5mm, depending on the application.

The clinch edge design ensures smooth and precise movement of goods.

Key Features:

1. The belt offers excellent resistance to corrosion and abrasion.

2. It is capable of withstanding high temperatures, making it suitable for hot conveying applications.

3. The clinch edge design eliminates the need for additional tracking devices, reducing maintenance costs.

4. The belt’s smooth surface prevents product damage and allows for easy cleaning.

5. It provides consistent and reliable performance, minimizing downtime.

Advantages:

1. Increased Efficiency

The smooth movement of the belt ensures efficient and uninterrupted material flow.

2. Versatility

The belt is suitable for a wide range of industries, including food processing, automotive, and pharmaceuticals.

3. Cost-effective

With its long lifespan and low maintenance requirements, the belt offers a cost-effective solution.

4. Customizable

The belt can be customized to meet specific application requirements, including length, width, and material.

5. Safety

The clinch edge design reduces the risk of product spillage and ensures worker safety.

Applications:

1. Food Industry

The belt is ideal for conveying food products, ensuring hygienic and efficient processing.

2. Automotive Industry

It is used for transporting parts during assembly and production processes.

3. Pharmaceutical Industry

The belt is suitable for conveying delicate medical products, maintaining product integrity.

4. Packaging Industry

It assists in the smooth movement of packages during packaging and distribution.

5. Manufacturing Industry

The belt facilitates the handling of various materials in manufacturing operations.