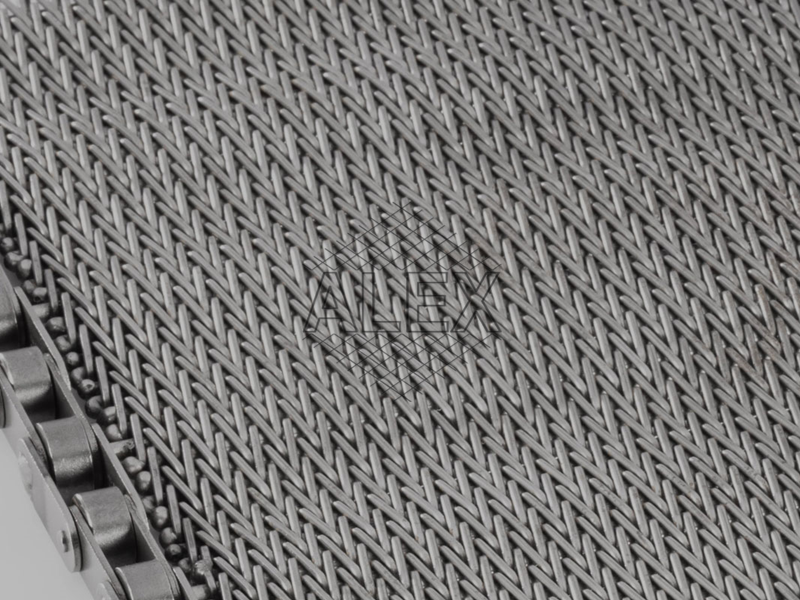

What is Compound Wire Belt?

The wire belt is a high-quality product designed for various industrial applications.

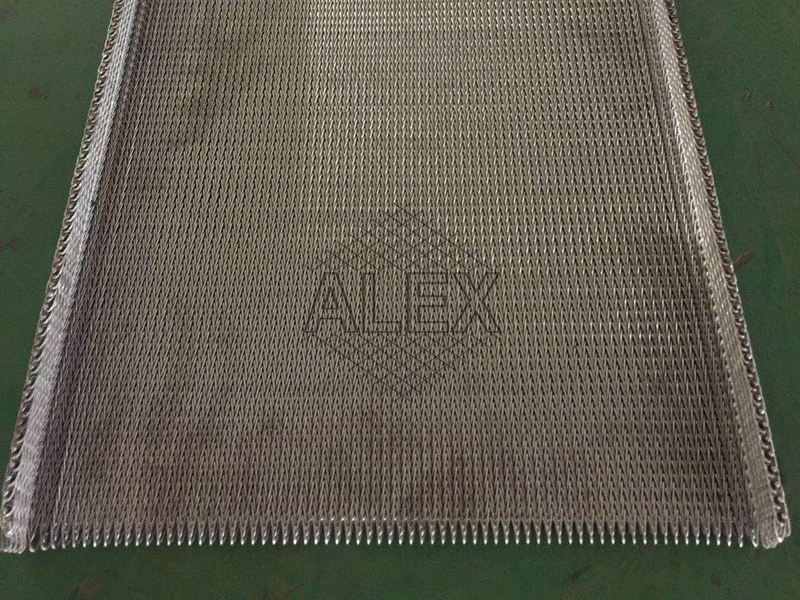

It is available in a wide range of sizes, typically ranging from 0.5mm to 3mm in diameter.

Its width can vary from 100mm to 2000mm, accommodating diverse production requirements.

Key Features:

1. Durable Construction

The belt is made from corrosion-resistant stainless steel, ensuring longevity and reliable performance in demanding environments.

2. Enhanced Stability

The belt’s unique compound structure provides excellent stability, preventing distortion or sagging during operation.

3. Versatile Design

Its modular construction allows for easy customization and adaptation to different conveyor systems, ensuring seamless integration.

4. Smooth Operation

The precisely formed wire loop enables smooth and consistent movement, minimizing friction and reducing the risk of product damage.

Advantages:

1. High Strength

The belt exhibits exceptional tensile strength, allowing it to handle heavy loads and endure prolonged usage without deformation.

2. Easy Maintenance

Its simple structure facilitates straightforward cleaning and maintenance, minimizing downtime and maximizing productivity.

3. Chemical Resistance

The stainless steel material used in the belt’s construction resists the corrosive effects of chemicals, ensuring durability and reliability.

4. Cost-Effective

Its long lifespan and low maintenance requirements contribute to overall cost savings.

Applications:

1. Conveyor Systems

The belt is ideal for conveying products in industries such as food processing, pharmaceuticals, and packaging.

2. Heat Treatment

Its efficient heat transfer properties make it suitable for applications like drying, cooling, and heat treatment processes.

3. Industrial Ovens

The belt’s heat resistance and stability make it a reliable choice for use in high-temperature industrial ovens.

4. Automotive Manufacturing

It can be used in automotive assembly lines for tasks such as painting, drying, and curing processes.