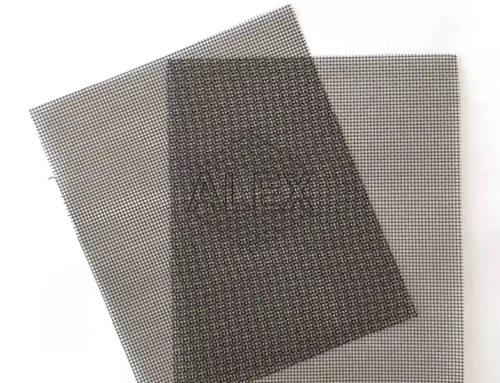

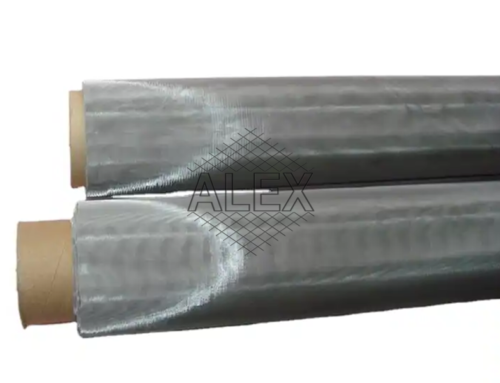

316 Wire Mesh is also named 316 stainless steel wire mesh.

Its wire diameter precision for optimal strength and flexibility.

This stainless steel wire mesh is suitable for both indoor and outdoor applications.

1. Advantages over Other Materials:

(1) Outperforms traditional materials in harsh environments.

(2) Exceptional longevity, reducing replacement and maintenance costs.

(3) Resists pitting and crevice corrosion for sustained performance.

(4) Maintains structural integrity under heavy loads and stress.

(5) Non-reactive nature makes it suitable for sensitive applications.

(6) Enhances safety with fire-resistant and non-combustible properties.

(7) Provides superior durability compared to alternative wire meshes.

(8) Minimal maintenance requirements, saving time and resources.

(9) Optimal for applications requiring hygienic and sterile conditions.

(10) Complements modern architectural designs with a sleek appearance.

(11) Environmentally friendly with 100% recyclable stainless steel.

(12) Reduces downtime due to its high reliability and stability.

2. Industrial Applications:

(1) Petrochemical industry for efficient filtration and separation.

(2) Aerospace industry for reliable structural components.

(3) Power generation plants for corrosion-resistant components.

(4) Water treatment facilities for effective filtration processes.

(5) Chemical processing industries for corrosive environment applications.

(6) Medical equipment manufacturing for sterile environments.

(7) Architectural applications for modern and durable design elements.

(8) Automotive industry for reliable and long-lasting components.

(9) Food and beverage processing for hygienic manufacturing.

(10) Marine industry for corrosion-resistant marine equipment.

(11) Pharmaceutical manufacturing for sterile processing environments.

(12) Mining industry for durable screening and sieving solutions.

3. Customization Options:

(1) Various mesh sizes tailored to specific filtration needs.

(2) Custom shapes and dimensions for unique project requirements.

(3) Different weave patterns to accommodate diverse applications.

(4) Electropolishing options for enhanced surface aesthetics.

(5) Specialized coatings for increased chemical resistance.

(6) Tailored packaging solutions for ease of transportation and storage.

(7) Precision cutting services for convenient on-site installation.

(8) Custom labeling and branding for product traceability.

(9) Optional certifications for industry-specific compliance.

(10) Collaborative design support for complex projects.

(11) Batch customization for large-scale industrial applications.

(12) Continuous innovation in response to evolving industry demands.

4. Environmental Sustainability:

(1) Stainless steel’s recyclability contributes to a green manufacturing process.

(2) Long product lifespan reduces the need for frequent replacements.

(3) Low maintenance requirements decrease the use of cleaning chemicals.

(4) Energy-efficient production processes minimize environmental impact.

(5) Stainless steel’s non-toxic nature ensures safe end-of-life disposal.

(6) Reduction in downtime enhances overall industrial energy efficiency.

(7) Contributes to LEED and other green building certifications.

(8) Supports sustainable practices across various industries.

(9) 316 wire mesh is compliant with RoHS directives.

(10) Eco-friendly packaging options available for conscientious clients.

(11) Innovation focused on minimizing environmental footprint.

(12) Ongoing commitment to sustainable manufacturing practices.