Honeycomb belting offers superior performance, improved efficiency, and exceptional durability with advanced materials and construction techniques.

Applications

1. Conveyor systems for bulk material handling

2. Food processing and packaging equipment

3. Automated assembly lines

4. Airport baggage handling systems

5. Pharmaceutical and chemical processing

6. Electronics and semiconductor manufacturing

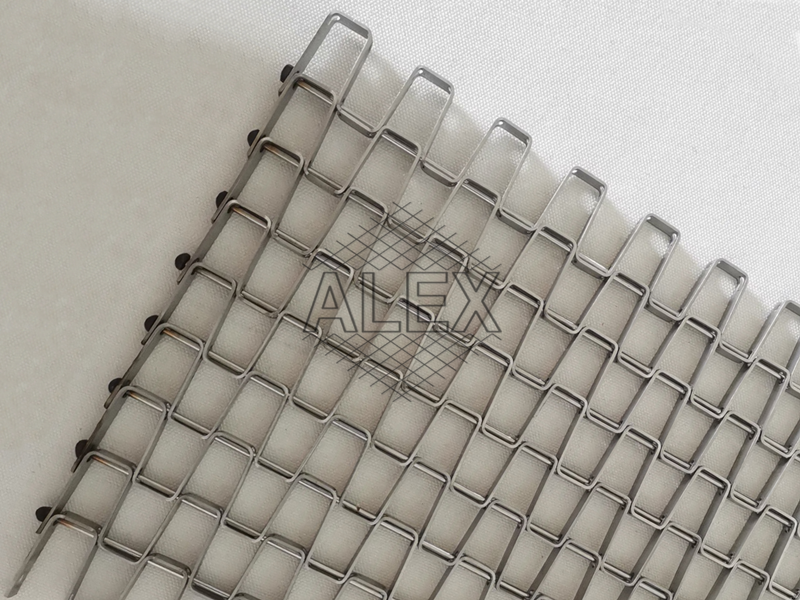

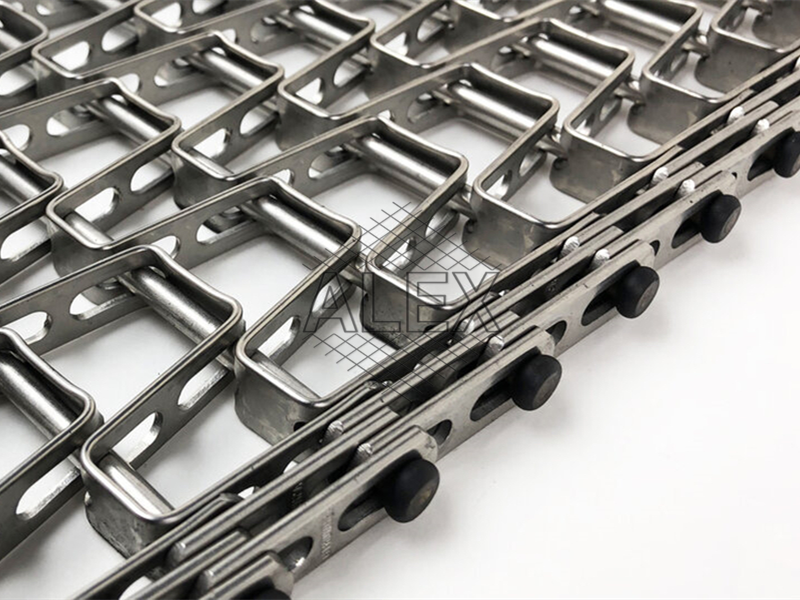

High-Strength Construction

The belting is constructed using a unique honeycomb structure, composed of lightweight yet incredibly strong materials such as fiberglass or carbon fiber composites.

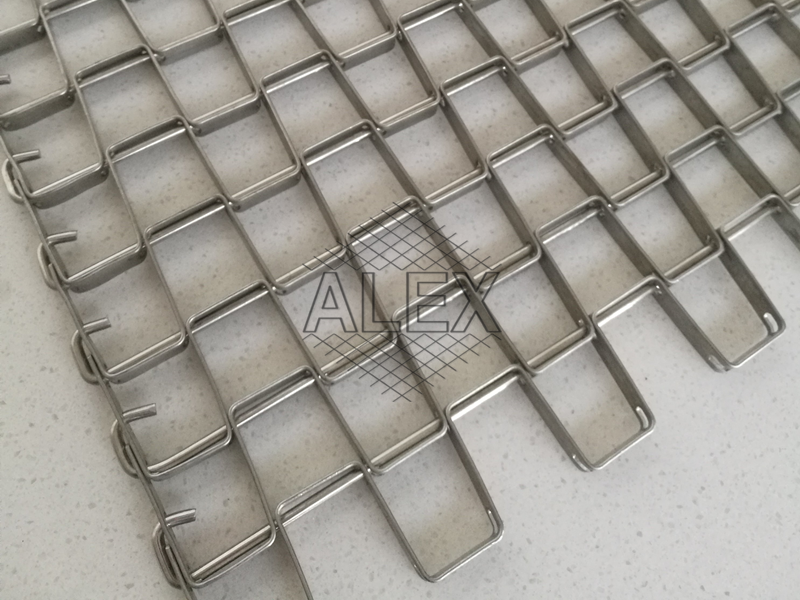

Lightweight and Energy Efficient

Due to its lightweight construction, the belting significantly reduces the overall weight of conveyor systems.

Enhanced Durability and Longevity

It exhibits exceptional resistance to wear, abrasion, and impact, making it an ideal choice for applications that involve heavy-duty conveying tasks.

Improved Traction and Tracking

Its honeycomb structure facilitates excellent traction, promoting efficient and reliable movement of conveyed materials.

Customization Options

The belting is available in a wide range of sizes, configurations, and surface patterns, allowing for customization to meet specific application requirements.

Hygienic and Easy to Clean

For industries that demand high standards of cleanliness and sanitation, honeycomb belting is an ideal choice.