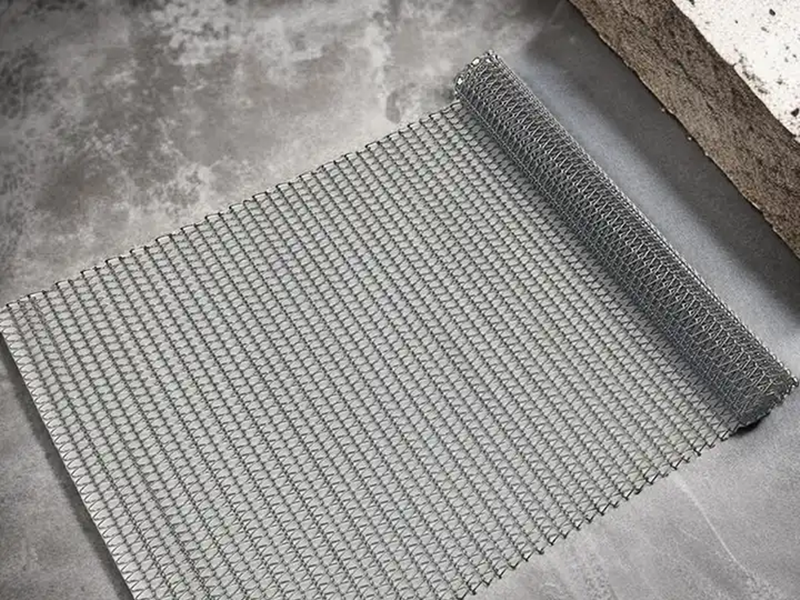

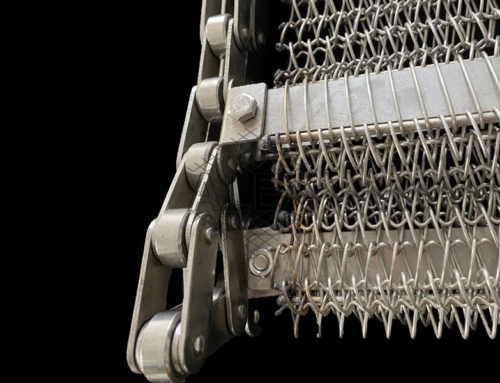

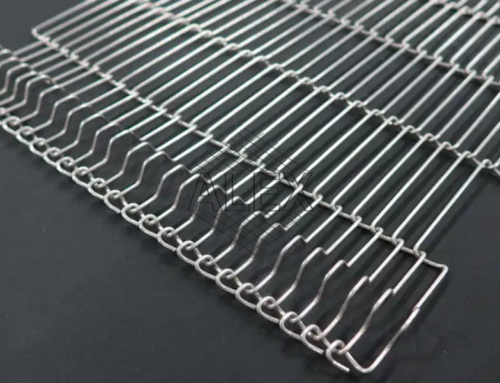

Balanced Mesh Belt is also widely known as balanced wire belt.

This wire mesh belt could revolutionize your operations.

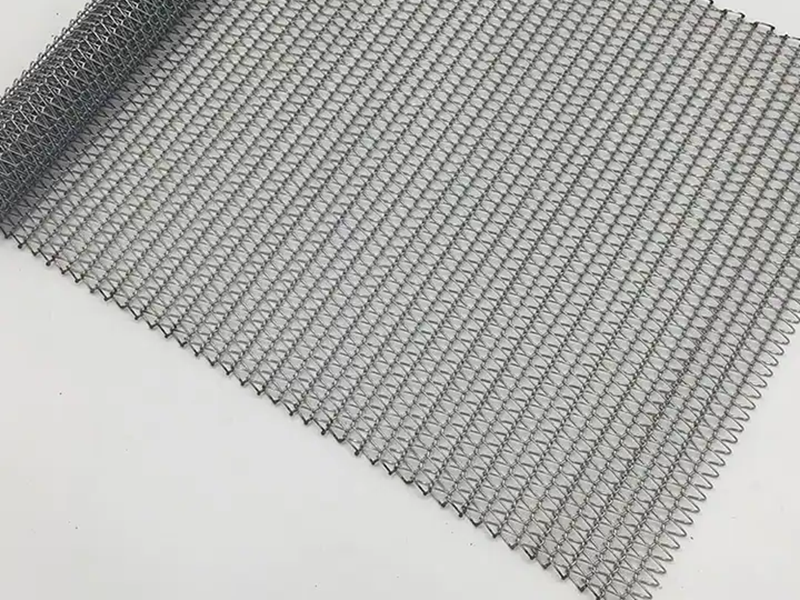

1: Unique Features

(1) Singular design for optimal efficiency.

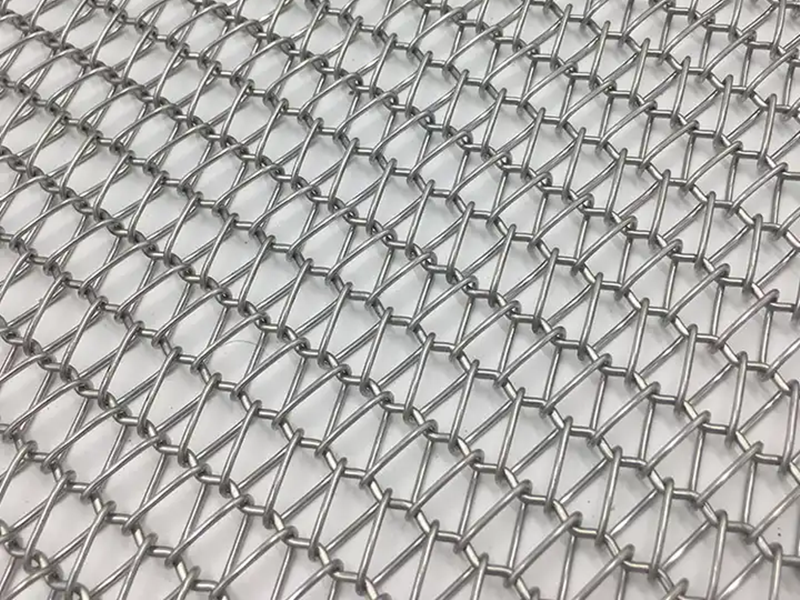

(2) Exceptional durability in diverse industrial applications.

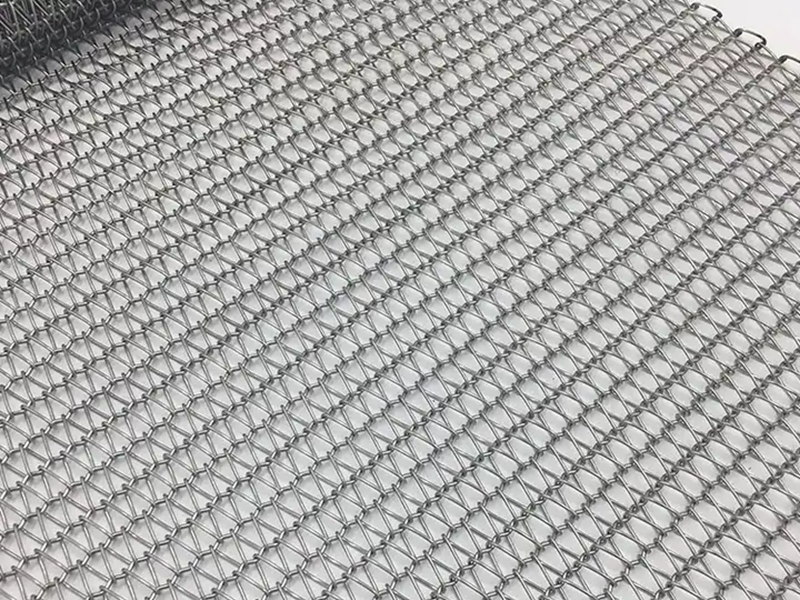

(3) Precision engineering for seamless performance.

(4) Singular focus on enhancing production processes.

(5) Unmatched flexibility for various material handling needs.

(6) Maximum strength with a singular weave pattern.

(7) Seamless integration with automated systems.

(8) Singular tracking system for precision movement.

(9) High-temperature resistance for extreme conditions.

(10) Singular belt surface for reduced friction.

(11) Elevated corrosion resistance for extended lifespan.

(12) Singular material choices for specific industry demands.

(13) Enhanced safety features with a singular design.

(14) Minimal maintenance requirements for cost efficiency.

(15) Singular adaptability to different conveyor configurations.

2: Applications

(1) Singular solutions for food processing industries.

(2) Elevate your packaging efficiency with the belt.

(3) Singular role in the automotive manufacturing process.

(4) Enhance the textile industry with the technology of this belt.

(5) Singular applications in pharmaceutical production.

(6) Optimize your metalworking operations with the belt.

(7) Singular contributions to the electronics manufacturing sector.

(8) Improve wood processing efficiency with the belt.

(9) Singular role in the chemical and petrochemical industries.

(10) Elevate the performance of glass manufacturing processes.

(11) Singular applications in the renewable energy sector.

(12) Enhance your mining operations with Balanced Mesh Belt.

(13) Singular contributions to the aerospace industry.

(14) Optimize agriculture processes with its technology.

(15) Singular applications in logistics and distribution centers.

3: Advantages

(1) Singularly boost production output and efficiency.

(2) Singularly reduce downtime with reliable performance.

(3) Enhance product quality with precise material handling.

(4) Singularly improve workplace safety standards.

(5) Optimize resource utilization with the wire belt.

(6) Singularly adapt to changing production requirements.

(7) Reduce operational costs with minimal maintenance needs.

(8) Singularly withstand harsh environmental conditions.

(9) Improve overall equipment lifespan with durable design.

(10) Singularly comply with industry regulations and standards.

(11) Boost employee morale with a reliable conveyor system.

(12) Singularly streamline production processes.

(13) Ensure consistent product flow with the belt.

(14) Singularly reduce waste in manufacturing processes.

(15) Enhance corporate sustainability with efficient material handling.

4: Future Outlook

(1) Singularly shaping the future of conveyor technology.

(2) Pioneering advancements in material handling systems.

(3) Singularly contributing to Industry 4.0 evolution.

(4) Balancing innovation and sustainability for future growth.

(5) Singularly addressing emerging challenges in conveyor systems.

(6) Anticipating future industry demands with the conveyor belt.

(7) Singularly driving efficiency in the era of smart manufacturing.

(8) Contributing to a more sustainable and connected industrial landscape.

(9) Singularly supporting global initiatives for efficient production.

(10) Balancing technology and environmental responsibility for a brighter future.

(11) Singularly adapting to the evolving needs of diverse industries.

(12) Paving the way for smarter, greener, and more efficient manufacturing.

(13) Singularly embracing the challenges of the Fourth Industrial Revolution.

(14) Anticipating and meeting the needs of future material handling demands.

(15) Balancing progress and responsibility for a sustainable industrial future.