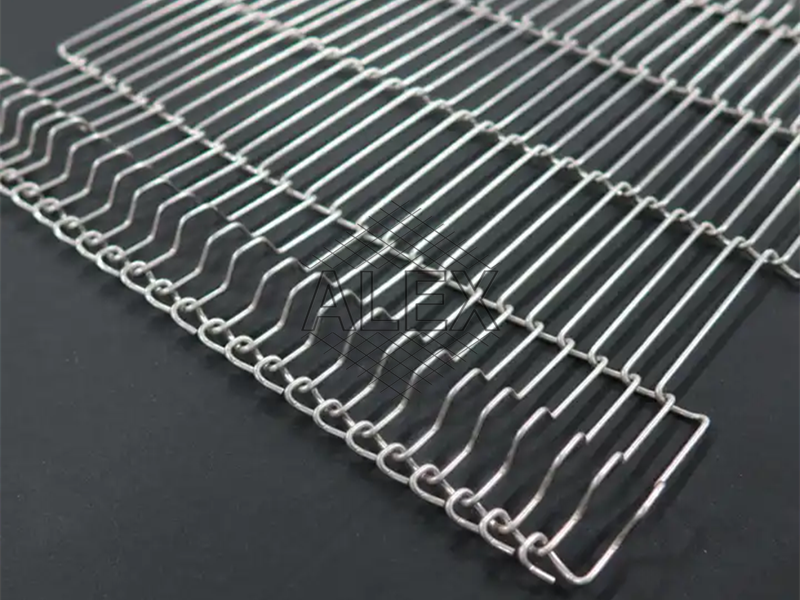

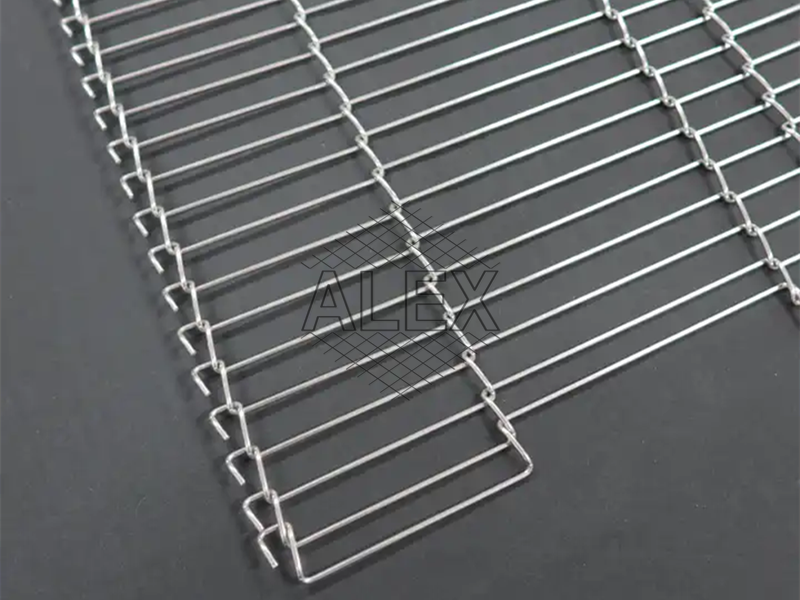

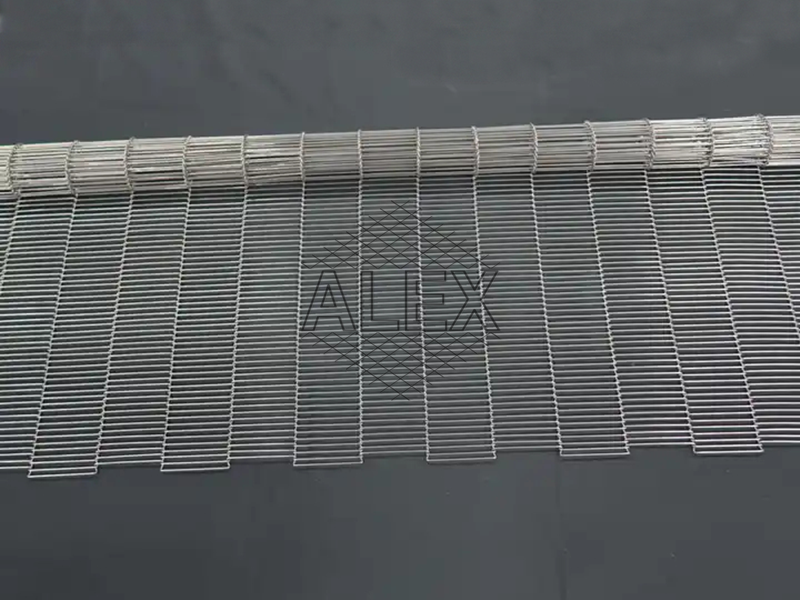

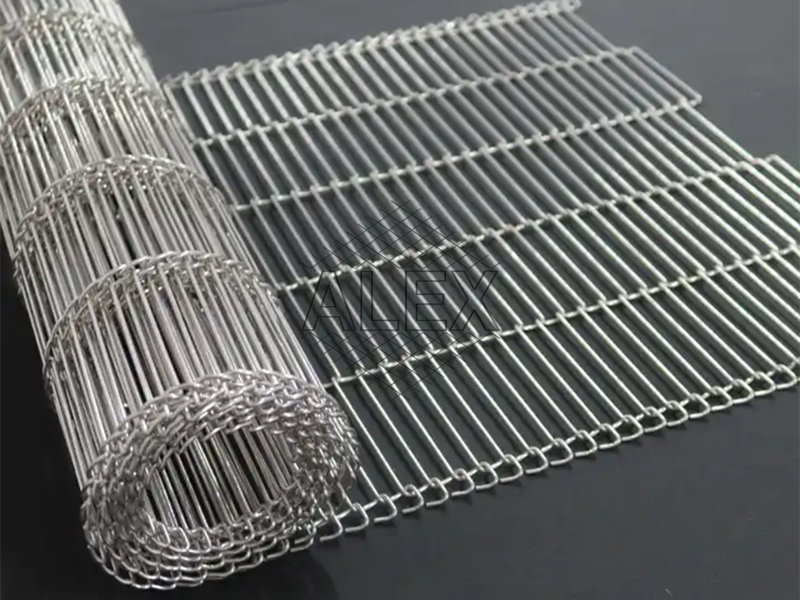

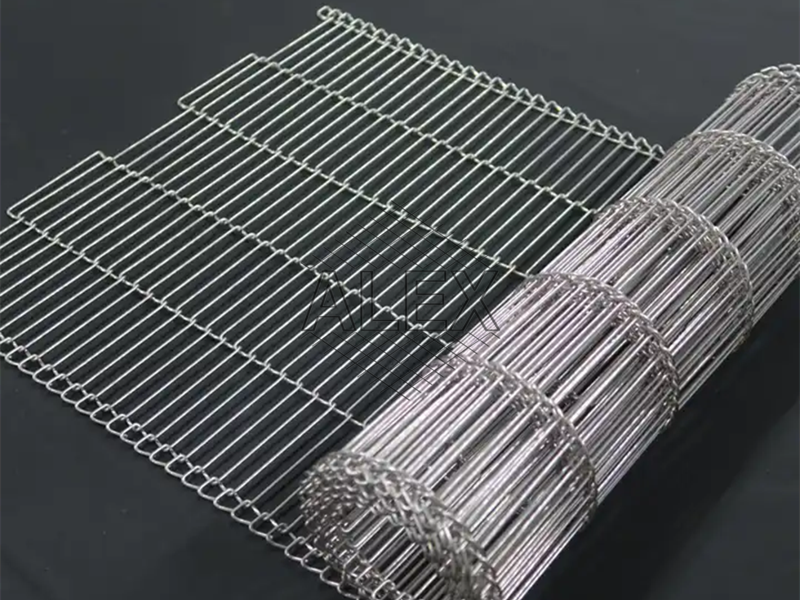

Flat Flex Wire Mesh Belt is also named flat flex conveyor belt.

The belt is designed for conveying a wide range of products.

This wire mesh belt is customizable options for specific requirements.

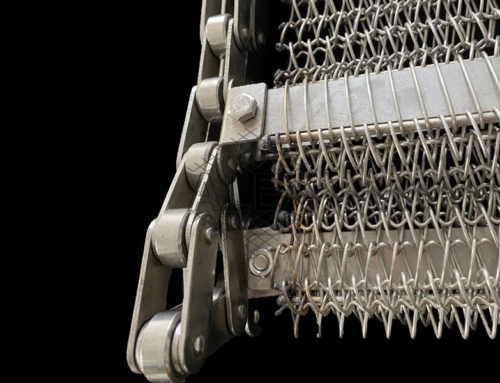

1. Construction:

(1) Interlocking wire design for strength.

(2) High-grade stainless steel construction.

(3) Precision welding for enhanced stability.

(4) Open mesh structure facilitates easy cleaning.

(5) Smooth edges prevent product damage.

(6) Resistant to wear and tear for prolonged use.

(7) Lightweight yet robust for efficient operation.

(8) Designed to minimize belt stretch.

(9) Options for reinforced edges for added strength.

(10) Available in various belt widths for versatility.

2. Applications:

(1) Food processing for hygienic material handling.

(2) Heat treatment processes in industrial ovens.

(3) Packaging lines for smooth product transition.

(4) Automotive manufacturing for assembly lines.

(5) Chemical processing for corrosive environments.

(6) Electronics industry for delicate component handling.

(7) Textile industry for seamless material flow.

(8) Pharmaceutical production for hygiene compliance.

(9) Agricultural processing for bulk material handling.

(10) Mining operations for efficient ore transportation.

3. Performance Benefits:

(1) Minimized downtime for increased productivity.

(2) Consistent and reliable material conveying.

(3) Low friction design for energy efficiency.

(4) Easy to clean, ensuring hygienic standards.

(5) Reduces product waste with smooth transitions.

(6) Resistant to adverse environmental conditions.

(7) Customizable for specific operational needs.

(8) Improved worker safety with reliable operation.

(9) Long-lasting performance for a solid ROI.

(10) Adaptable to various speed and load requirements.

4. Customization Options:

(1) Custom belt lengths for diverse Conveyor Systems.

(2) Specialized mesh configurations for unique materials.

(3) Color-coding for easy visual identification.

(4) Variable wire thickness for enhanced strength.

(5) Optional coatings for additional corrosion resistance.

(6) Attachment options for specialized handling.

(7) Integration of tracking systems for precision.

(8) Perforations for liquid drainage applications.

(9) Adjustable belt tension for optimal performance.

(10) Collaboration with engineers for tailored solutions.